Go with the flow

All preparations for the first offshore demonstration of the Vibrojet® monopile installation technique are in full swing. Hein van Opstal, Paula van Lieshout and Pierre Bouchet of GBM Works walk David de Jager through the technology, challenges and collaboration behind this promising technology for quieter, more efficient monopile installation at the Mammoet shipyard in Schiedam.

Back in 2023, GROW-to-GO already reported on the Vibrojet® technology in a previous episode called ’Shaken and stirred’, where the focus was on early-stage onshore tests and modelling work. Since then, the technology has come a long way. In the SIMPLE III project, the technology will be tested under real offshore conditions near the 760 MW Ecowende offshore wind project, Hollandse Kust West. In Hollandse Kust West several monopiles will be installed with this technology. Monopiles that should be capable of supporting 15 MW turbines.

|

|

Force and water

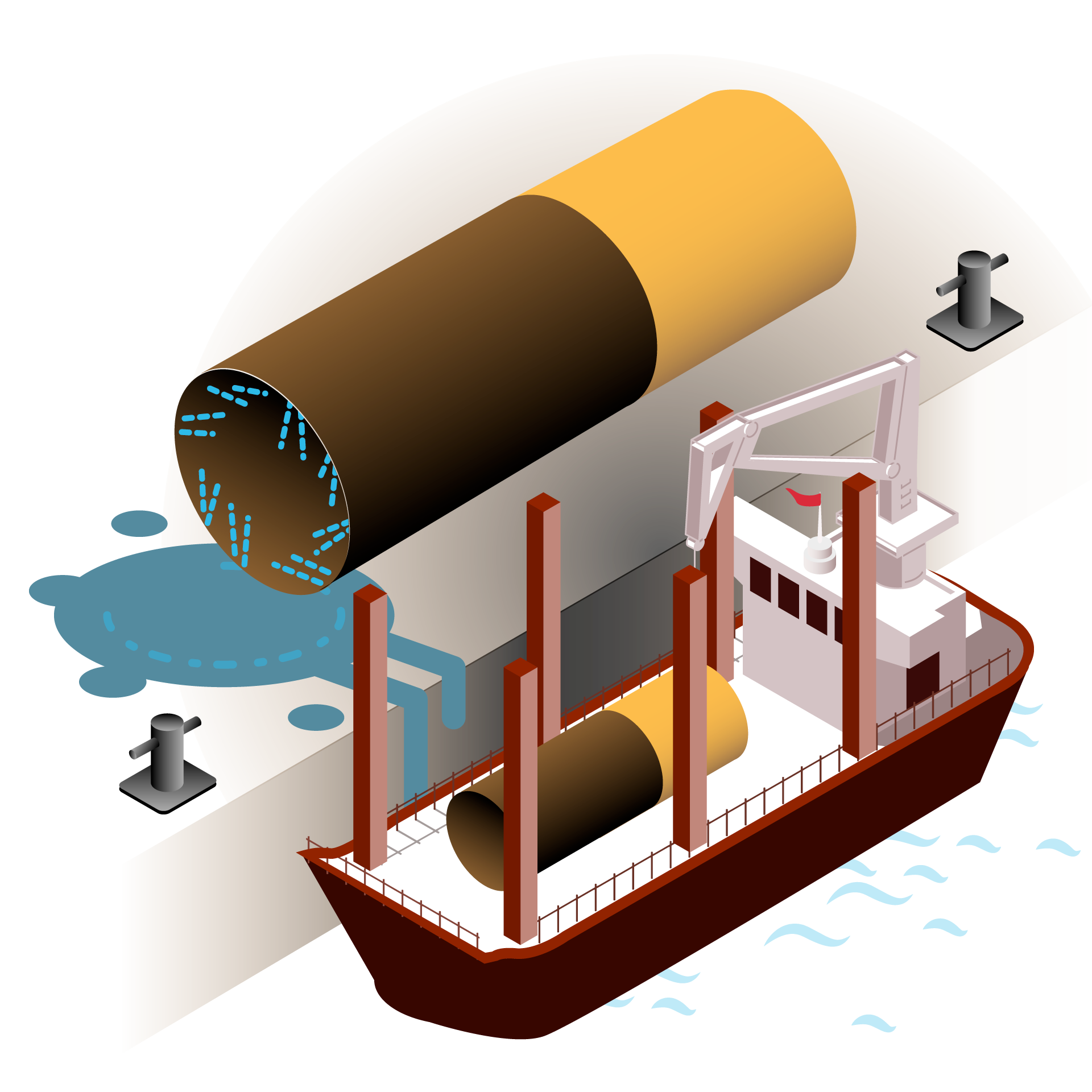

Just to refresh my memory, how did the technique work again? At its core, the Vibrojet® combines two proven installation principles – vibration and water jetting – into a single, integrated method. While traditional monopile driving relies on impact hammers that generate significant underwater noise, the Vibrojet® uses controlled vertical vibration to drive the pile into the ground, assisted by a ring of precision nozzles near the pile base that inject high volumes of water.

|

|

This process temporarily fluidises the soil, reducing friction and resistance, allowing the pile to penetrate the seabed with minimal force. By lowering the energy required for installation, the system not only reduces costs and environmental impact but also extends the working life of equipment and increases efficiency in challenging soil conditions.

The system can adjust vibration and water flow in real time, using sensor data from inside the pile. Measurements of soil resistance, pore pressure and strain feed into GBM Works’ models, allowing operators to optimise performance on the spot. The same process can even be reversed for decommissioning, offering a cleaner end-of-life solution for offshore wind farms.

|

|

The monopile

The monopile is equipped with an array of internal and external sensors to monitor structural integrity, fatigue, and pressure distribution during installation. “These sensors, Hein explains, are essential for validating our models and confirming the effectiveness of the jetting system, which fluidises the soil at the base of the pile to reduce friction.

Have a look at Hein's profile on LinkedIn

|

|

Engineering under pressure

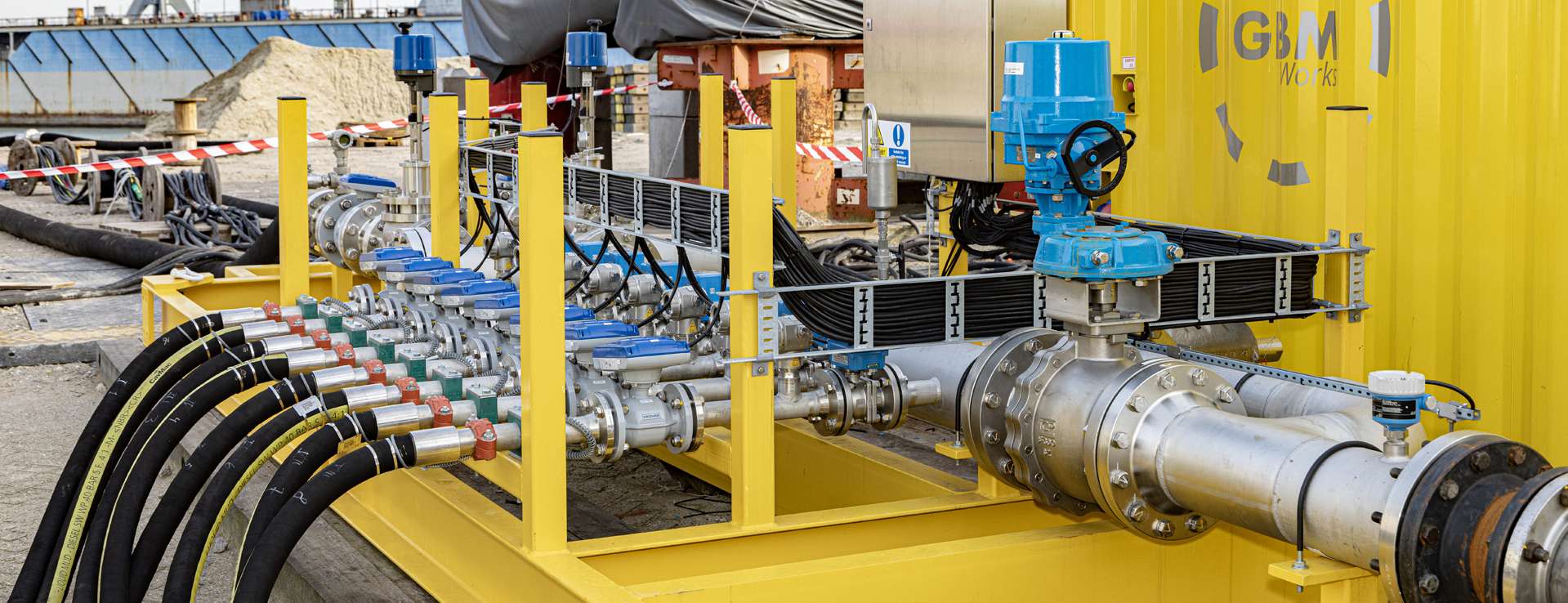

“A lot had already been developed, but bringing the system from design to manufacturing, and now to installation, required intensive coordination,” Paula says. In the last weeks before deployment, her focus has been on the final painting, sensor calibration, and making sure every part of the system works as expected.

She also highlights the growing industry interest: “We started with 11 industrial partners. That has now grown to 14, soon 15 – and we’re still in talks with more. The combination of renewable energy demand and the need to reduce environmental impact clearly resonates.”

Have a look at Laura’s profile on LinkedIn

|

|

The power of water

“The system can pump up to 400 cubic metres of water per hour,” Pierre explains. “That’s enough to fill an Olympic swimming pool in 5 to 6 hours. The water is distributed through 48 nozzles at the base of the monopile, designed to fluidise the soil just enough to enable smooth pile installation – and, if needed, decommissioning too.

Have a look at Pierre’s profile on LinkedIn

Atlantic Shores offshore wind: expertise in project development and operating wind farms

bp: expertise in project development and operating wind farms

Cape Holland: expertise in installation equipment

Carbon Trust: innovation platform for offshore wind

|

|

According to Pierre, one of the biggest engineering challenges was ensuring precise and safe control offshore: “Everything needs to be monitored and operated from the vessel – it’s about robust design, reliability, and safety under real offshore conditions.”

Deltares: expertise in geotechnical research

DEME Offshore: expertise in installation

Ecowende: expertise in installing and operating wind farms

EnBW: expertise in project development and operating wind farms

|

|

Countdown to offshore

With weeks to go until the offshore test campaign, the team is running final pre-tests and preparing for mobilisation. While Paula and Hein will be coordinating from shore, Pierre will be closely involved in the offshore execution, working alongside Van Oord and CAPE Holland to combine vibration and jetting into one integrated installation method.

|

|

Will the Vibrojet® live up to its promise? The coming weeks will tell. As David wraps up his visit to the Mammoet ship yard, one thing is clear: this test marks a major step forward in reducing noise and improving efficiency in offshore wind installation.

Seaway7: expertise in the installation of wind farms

Shell: expertise in project development and operating wind farms

TNO: expertise in modelling of sound created by installation techniques

TotalEnergies: expertise in project development and operating wind farms

|

|

New developments

Since the recording of the podcast, the SIMPLE III Offshore Tests were completed successfully.

The tests provided valuable offshore drivability and noise data, gathered during the Vibrojet® installations. This delivers the project's primary objective: demonstrating the technology in an environment closely resembling that of the commercial project at Hollandse Kust West, where it will be commercially deployed for the first time. This data is collected in support of reaching Technology Readiness Level (TRL) 7.

Van Oord: expertise in the installation of wind turbines

Vattenfall: expertise in project development and operating wind farms

Waterkant/Waterekke: expertise in project development and operating wind farms

© GROW ’26